Utilities have used oil-insulated switchgear for decades. But times change.

The modern grid continues to evolve. Sustainability pressures continue to mount.

It’s time for a new approach. It’s time for S&C’s Vista® Underground Distribution Switchgear.

Product Overview

Vista Underground Distribution Switchgear

Vista switchgear solves difficult switching and protection challenges and improves reliability using SF6 insulating gas. Built with the user in mind, it only takes one person to operate, and includes other features designed for operator safety, such as highly visible gaps.

Vista Green Underground Distribution Switchgear

Vista Green switchgear provides the same features, design, and reliability benefits of Vista switchgear without the SF6 gas. This alternative instead uses a hermetically sealed CO2 mix that reduces its global warming potential by 97% compared to SF6 switchgear.

Vista SD Underground Distribution Switchgear

Vista SD switchgear is another eco-friendly option that uses solid-dielectric material instead of an insulating gas. With its highly visible breaks, flexible design, and front-facing terminations, this switchgear is particularly advantageous in vault applications and at higher altitudes.

Advantages

Vista, Vista Green, and Vista SD switchgear are built to minimize reliability risks and deliver significant cost savings.

*Applies to Vista and Vista Green switchgear only.

**Applies to Vista Green and Vista SD switchgear only.

Construction & Design

Explore the construction and key features of this product using the 3D product viewer below. For instructions on how to use the viewer, click the Help button next to the black question mark icon.

Features

Green Insulation Technology

Insulation has drastically reduced or zero global-warming potential.*

Manual or Automatic

Choose automatic, manual, or remote operational capabilities with a motor operator.

Dust, Corrosion & Leak-Proof

Prevent leaking, rusting, or contamination to switchgear with a sealed design.

Smaller Footprint

The switchgear's compact, low-profile design minimizes footprint.

Visible Open Gap

Easily confirm closed, open, and grounded** positions through large viewing windows.

Multiple Installation Styles

Choose from pad-mounted, vault-mounted, single-way wind-turbine**, or UnderCoverTM style** units.

No External Grounds

Ground medium-voltage cables using a standard internal ground switch. External grounds are not required.**

Low Maintenance

Minimal mechanical maintenance is required once a unit is installed; only an annual visual inspection is recommended.

Overcurrent Control

Superior coordination, flexibility, and reliability are made possible with a self-powered and user-friendly control.

Why Go Green?

The same features. The same design and benefits. No SF6. A 97%-reduced global warming potential.

Explore the sustainable power of Vista Green switchgearGuidebooks

Are you considering alternatives to oil-insulated switchgear? The guidebook summarizes how making the switch from oil-insulated switchgear to Vista, Vista Green, or Vista SD switchgear can be advantageous from an operational and maintenance standpoint.

As the grid becomes more complex, utilities are facing a variety of challenges pressuring them to reassess their medium-voltage switchgear. In fact, some switchgear even poses risks that increase operation and maintenance (O&M) expenses while reducing reliability. As utilities reevaluate the switchgear on their system, they importantly should consider the scope of the challenges they may face and the breadth of switchgear products available that can best meet the needs of today’s grid.

Case Studies

Customer successes achieved using Vista, Vista Green, or Vista SD switchgear.

West Coast Utility

Improved reliability and perfect coordination, while use of UnderCover Style units makes switchgear virtually invisible in the community.

Read MoreMidwest Utility

Improved reliability, while sectionalizing and coordination are provided with the existing scheme.

Read MoreArizona Utility

Utility standardizes Vista switchgear on its system after this project’s success.

Read More*Applies to Vista Green and Vista SD switchgear only.

**Applies to Vista switchgear only.

Need Support?

S&C is here to help you through any stage in your grid-modernization journey, from system studies to installation videos. Explore more below.

Product Details

Medium-voltage switching and protection equipment doesn’t need to be complicated. Manual Vista and Vista Green switchgear is purpose-built to simplify operations while providing an intuitive solution to managing complex medium-voltage power-delivery needs.

S&C Remote Supervisory Vista and Vista Green switchgear provide automated switching and fault protection and — when applied in S&C’s High-Speed Fault-Clearing System — can also perform auto-sectionalizing without tripping the main breaker. It incorporates the same outstanding features as Manual Vista and Vista Green switchgear and can be specified with a communication and control equipment group, for a completely integrated, self-powered switching and protection package.

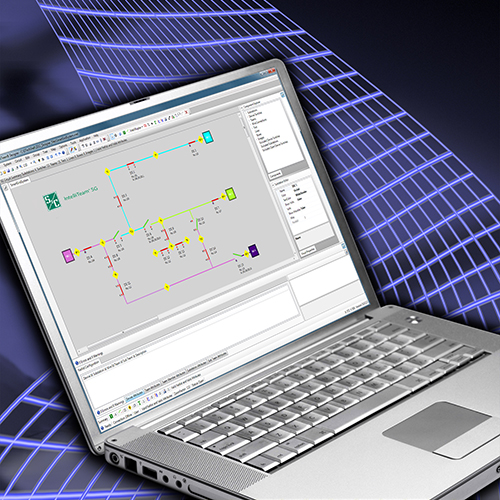

- Your choice of remote terminal unit, including S&C’s 6800 Series Automatic Switch Controls. These sophisticated controls support S&C’s self-healing, scalable IntelliTeam® SG Automatic Restoration System — a universal Smart Grid solution offering unmatched interoperability.

- Your choice of communication platform or device, including fiber optics or S&C’s SpeedNet™ Radio.

- Motor operators provide three-second operation of load-interrupter switch ways and three-pole group-operated fault interrupter ways. They’re easily moved between ways . . . no reconfiguration necessary.

- Three-phase current sensing and line-to-ground voltage sensing for every motor-operated way.

Each S&C Source-Transfer Vista and Vista Green switchgear unit provides fully automatic primary-selective service and fault protection for one, two, or three-pole critical load circuits. This Smart Grid solution incorporates the same outstanding features as Manual Vista or Vista Green switchgear, plus S&C’s Micro-AT® Source-Transfer Control, motor operators, three-phase voltage sensing on source ways, and voltage transformers for control power. It's available in common-bus and split-bus configurations. Furnished in ratings through 38 kV, Source-Transfer Vista and Vista Green switchgear feature carefully integrated components that ensure compatibility — all factory-assembled and checked-out.

For larger or more complex source transfer systems, multiple Source-Transfer Vista and Vista Green switchgear units equipped with Micro-AT Source Transfer Control or 6802 Automatic Switch Control can handle any number of sources and critical loads.

- Micro-AT Source-Transfer Control offers self-healing response to distribution system problems. Transfers on loss of source, voltage unbalance, or any source-side open-phase condition. It’s easy to set up . . . all settings are keypad-programmable, calibration is automatic. Optional overcurrent-lockout feature prevents automatic transfer operation that would close a source load-interrupter switch into a fault. Optional communications card lets you rapidly upload event log to your PC, download standard settings.

- Motor operators on load-interrupter switch ways provide automatic switching between the sources. Also provide automatic operation of bus-tie switch in split-bus configuration gear.

- Three-phase voltage sensing for each source. Three-phase current sensing furnished too when optional overcurrent-lockout feature is specified.

- Self-powered by voltage transformers.

- Exceptionally rugged enclosure construction and the industry’s finest finish. Provides extraordinary resistance to the elements, keep high-voltage components securely isolated from unauthorized access.

S&C Vista switchgear models with 15-kV loadbreak switches rated 40 kA symmetrical short time are an ideal fit for sectionalizing underground distribution networks. Switchgear in urban areas is frequently installed subsurface or in street or sidewalk vaults, so a compact size is generally required along with an ability to withstand routine flooding. Available fault-current levels also may be very high and exceed the capabilities of most compact and submersible switchgear. Few switchgear products offer all the capabilities needed to perform reliably under such difficult conditions.

S&C’s Vista switchgear offers a superior solution for adding switching points to urban distribution networks. Our 15.5-kV and 40-kA Vista switchgear models incorporating loadbreak switches with a momentary rating of 40 kA symmetrical provide all the features needed for vault and subsurface switching applications, including a fully submersible design that offers reliable performance even in vaults prone to flooding. Vista switchgear is gas-insulated, eliminating the maintenance and safety concerns associated with oil-insulated switchgear. And, unlike lower-rated switchgear, it eliminates the need to incorporate current-limiting devices, which are difficult to coordinate and increase operating complexity.

Vista SD Underground Distribution Switchgear is purpose-built to simplify operations and provide a medium-voltage switching and protection solution using a solid-dielectric insulation system instead of gas.

S&C Remote Supervisory Vista SD Underground Distribution Switchgear incorporates the same outstanding features as Manual Vista SD switchgear for either inline or PME and PMH configurations. Vista SD switchgear can be engineered with communication and control equipment for a completely integrated and self-powered switching and protection package.

Compact Pad-Mounted Style Vista and Vista Green switchgear improve aesthetics and reduce real-estate requirements — especially at 34.5 kV, where air-insulated gear is too large to be practical in many applications.

- Compact footprint and low profile — Pad-mounted enclosures feature hinged roofs and removable panels, providing convenient access to both the operating and termination components

- All cable terminations are located on one side of the gear. Minimizes operating clearances, reduces space requirements. A typical 15-kV Vista or Vista Green switchgear installation requires just 1/3 the space of conventional pad-mounted gear

- A single Vista or Vista Green switchgear unit accommodates up to six load-interrupter switches, fault interrupters, or combination of each. So more loads can be served from a single unit. Eliminates need for redundant switches and extra cabling, trenching, and box pads — and additional operating clearances needed between multiple units

- Operating controls are isolated from the cable compartment. Thanks to Vista and Vista Green switchgear’s innovative features, operating personnel are never exposed to medium-voltage during routine operations.

- Certified arc resistant per IEC 62271-200 for fault currents up to 25-kA symmetrical for 15 cycles . . . adds another level of safety for operating personnel.

Underground and out of sight — yet easy to operate from ground level — unique submersible UnderCover Style Vista and Vista Green switchgear is ideal where aesthetics are extremely important, or where space limitations make it difficult to site gear above ground.

- Gear can be installed exactly where it’s needed, reducing the costs associated with trenching and unnecessarily long cable runs

- All operating controls are located on top of the gear, easily accessible from ground level — and isolated from medium-voltage cables

- Integral “closed-open-grounded” positions on every switch and fault interrupter allow easy isolation and grounding of cables with no exposure to medium voltage

- One person, standing above grade, can easily perform all routine operations without handling cables or entering the underground vault

- Eliminates added time and complication of entering a confined space

- Certified arc resistant per IEC 62271-200 for fault currents up to 25-kA symmetrical for 15 cycles . . . adds another level of safety for operating personnel.

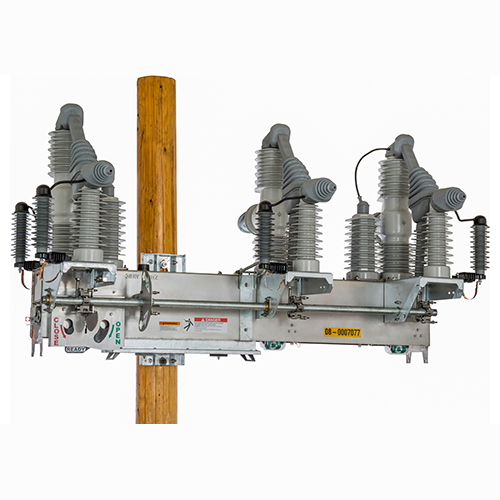

Vista and Vista Green switchgear in the Vault Mounted Style provides a compact switching and protection solution for subsurface applications, electrical rooms, and sidewalk vaults, where space is extremely limited. A single unit accommodates up to six load-interrupter switches, fault interrupters, or combination of each.

- Wet-vault-mounted style features a stainless-steel tank and fully submersible wiring, perfect for harsh environments

- Dry-vault-mounted style is ideal for electrical rooms and vaults that aren't subject to flooding

- Optional portable motor operator with 50-foot cord and remote control lets you perform switching outside the vault or in an adjacent room

- Operating controls are located away from cables. Personnel are never exposed to medium voltage during routine operations. Cable handling — particularly awkward in vaults — isn't necessary

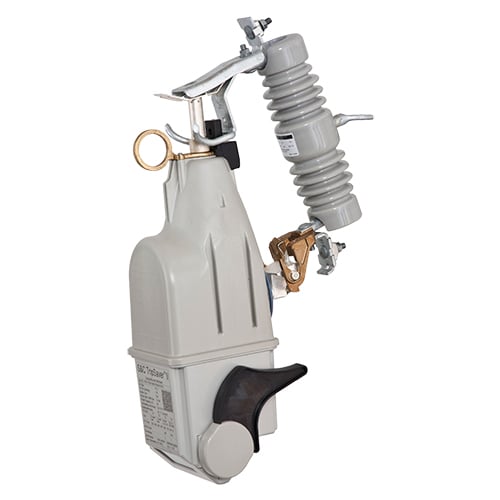

Single-Way Wind Turbine Style Vista or Vista Green switchgear are slim, single-way three-phase versions that are typically applied in wind turbine towers. They can fit through the typical 24-inch wide opening of the turbine door, and provide connection and switching points for the medium-voltage cables from the generator output. They are generally specified with resettable fault interrupters, but can also accommodate load-interrupter switches.

Single-Way Wind-Turbine Style Vista and Vista Green switchgear can be positioned along the inside wall of the tower, providing more space for personnel and equipment.

Developed for the U.S. military, small, lightweight Mobile Heavy-Duty Style Vista and Vista Green switchgear is specially designed to withstand the rigors of extended air transport at high altitude. Gear stacked two-high (to conserve space aboard an airplane) has passed the MIL Spec E-810 20-hour shaker-table vibration test, verifying they can withstand 10,000 miles of air travel, and that their performance is not affected by the low atmospheric pressure experienced during transport at an altitude of 40,000 feet.

This unique version of Vista and Vista Green switchgear is suitable for temporary or permanent installations. Comprised of two load-interrupter switch ways and four fault-interrupter ways, they feature an enclosure frame and integral skid constructed from heavy-duty I-beams and channels. Eyebolts and alignment pins on the top facilitate lifting and stacking. Turnbuckles, attached to eyebolts on the front and rear sides of the skid, hold the stacked units together during transport. Channels on the bottom allow forklift handling. Reinforced tabs on the skid allow the gear to be dragged along the ground. Plates, attached to the floor of the enclosure, protect the switchgear during transport and storage and can be removed to facilitate cable entry.

Vista and Vista Green switchgear are suitable for a variety of “special” applications. For example, when an existing conventional metal-enclosed switchgear lineup needed to be expanded to accommodate two additional feeders — but there was only room for one more bay — a new special bay was constructed externally matching the others, containing a unit of Vista switchgear.

Vista and Vista Green switchgear are much smaller than conventional air-insulated metal-enclosed gear. A typical 25-kV conventional metal-enclosed switchgear feeder bay is about 52 inches wide; the two bays required for this application thus would be 104 inches wide. But a three-way Vista switchgear unit housed inside the special bay is only 58 inches wide, reducing the space requirement by almost half.

Vista and Vista Green switchgear are operated from a control panel that is completely isolated from medium-voltage components. The position of each fault-interrupter disconnect — open, closed, or grounded — is easily seen through large viewing windows. With the disconnect in full view, operating personnel can verify the open gap and ground cables without having to remove elbows or T-bodies. And by using the optional push-button voltage indicator furnished, they can check voltage without moving cables. A door at the rear of the bay allows access to the elbow connectors.

Vista SD can be furnished with an optionally available pad-mounted style enclosure for above-grade installations. Pad-mounted enclosure meets IEEE C57.12.28 and C57.12.29. Available in mild steel or stainless steel.

Multi-way Vista SD switchgear can be used in submersible vaults with multiple source ways and/or multiple protected ways (taps).

Single-way Vista SD switchgear is ideally suited for use on the primary side of network transformers. Model 101 (fault interrupter) shown.

(On mobile, swipe left for remaining ratings information.)

| kV | Amperes, RMS | |||||||

|---|---|---|---|---|---|---|---|---|

| System Class | Max | BIL | Main Bus Cont. Current♠ | Short-Circuit, Sym. |

Fault Interrupter | Load-Interrupter Switch | ||

| Cont. and Load Dropping♠ | Ten-Time Duty-Cycle Fault-Interr., Sym. | Cont. and Load Dropping♠ | Mom. and One-Second, Sym. |

|||||

| 15.5 (12) |

15.5 (15.5) |

95 (95) |

600 (630) |

12 500 (12 500) |

200 (200) |

12 500 (12 500) |

600 (630) |

12 500 (12 500) |

| 25 000 (25 000) |

600 (630) |

25 000 (25 000) |

600 (630) |

25 000 (25 000) |

||||

| 27 (24) |

29 (29) |

125 (125) |

600 (630) |

12 500 (12 500) |

200 (200) |

12 500 (12 500) |

600 (630) |

12 500 (12 500) |

| 25 000 (25 000) |

600 (630) |

25 000 (25 000) |

600 (630) |

25 000 (25 000) |

||||

| 38 (36) |

38 (38) |

150 (150) |

600 (630) |

12 500 (12 500) |

200 (200) |

12 500 (12 500) |

600 (630) |

12 500 (12 500) |

| 25 000 (25 000) |

600 (630) |

25 000 (25 000) |

600 (630) |

25 000 (25 000) |

||||

♠ Other ratings are available. Contact your local S&C Sales Office for more information.

![]() 15-kV loadbreak switch models with a momentary rating of 40 kA symmetrical, 0.5 sec., are also available.

15-kV loadbreak switch models with a momentary rating of 40 kA symmetrical, 0.5 sec., are also available.

Refer to Specification Bulletins 681-31, 681-33, 682-31 and 683-31 for more details.

(On mobile, swipe left for remaining ratings information.)

| Voltage, kV | Amperes, RMS | ||||||||

| System Class | Max | BIL | Main Bus | Visi-Gap® Load-Interrupter Switch | Visi-Gap® Fault Interrupter | ||||

| Continuous Current | Short-Circuit, RMS, Symmetrical | Continuous, Load Dropping, and Load Splitting |

Momentary and Three-Second, Symmetrical | Three-Time, Duty-Cycle, Fault Closing, Symmetrical |

Continuous, Load Dropping, and Load Splitting |

Short-Circuit Interrupting | |||

| 15 (12) | 17.5 (17.5) | 95 (75) | 600 (630) | 16 000 | 600 (630) | 16 000 | 16 000 | 600 (630) | 16 000 |

| 27 (24) | 29 (29) | 125 (125) | 600 (630) | 12 500 | 600 (630) | 16 000 | 16 000 | 600 (630) | 12 500 |

![]() Parallel or loop switching. Load-interrupter switches and fault interrupters can switch the magnetizing current of transformers associated with this rating. Unloaded cable-switching capability: 10 amperes at 17.5 kV; 20 amperes at 29 kV. Load-interrupter switches and fault interrupters can also switch single capacitor banks through 1800 kvar.

Parallel or loop switching. Load-interrupter switches and fault interrupters can switch the magnetizing current of transformers associated with this rating. Unloaded cable-switching capability: 10 amperes at 17.5 kV; 20 amperes at 29 kV. Load-interrupter switches and fault interrupters can also switch single capacitor banks through 1800 kvar.

![]() Applicable to fault closing into Closed position.

Applicable to fault closing into Closed position.

![]() 200 amperes if fault interrupters are furnished with optional 200-ampere bushings.

200 amperes if fault interrupters are furnished with optional 200-ampere bushings.

![]() 12 500 amperes if fault interrupters are furnished with optional 200-ampere bushings.

12 500 amperes if fault interrupters are furnished with optional 200-ampere bushings.

Refer to Specification Bulletin 695-31 for more details.

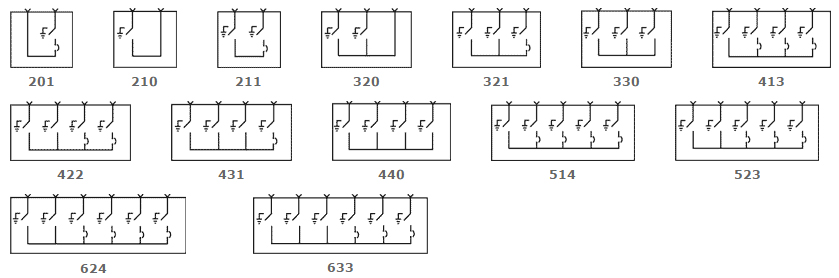

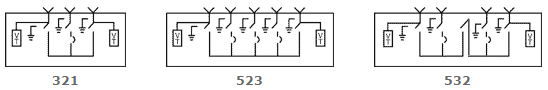

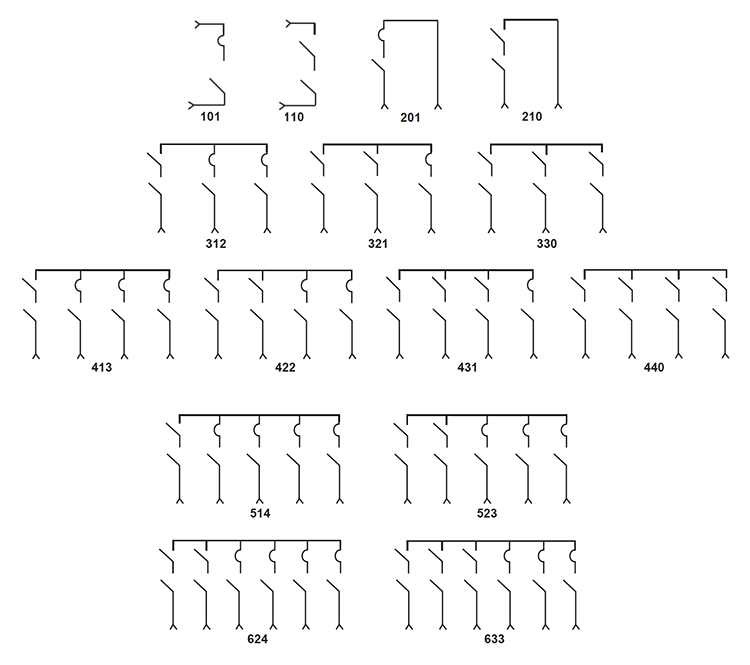

Vista and Vista Green switchgear can be furnished with up to six “ways” per unit, each consisting of a load-interrupter switch, fault interrupter, or bus tap.

Some typical configurations are shown below. The model number indicates the total number of ways, as well as the number of load-interrupter switch and fault-interrupter ways. For example, Model 321 has “3” ways — “2” load-interrupter switch ways and “1” fault-interrupter way, as shown below. Many other configurations are possible.

Model number indicates the total number of ways, as well as the number of load-interrupter switch ways and fault-interrupter ways. For example, Model 431 has “4” ways—“3” load-interrupter switch ways and “1” fault-interrupter way.

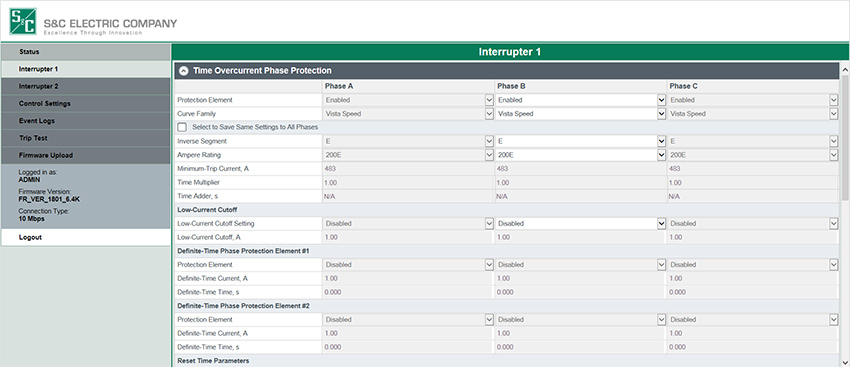

Vista, Vista Green, and Vista SD switchgear are furnished with fault-interrupter ways includes a unique microprocessor-based overcurrent control that detects faults and initiates operation of the resettable fault interrupters. Program the control in the shop or in the field using your personal computer via an easily connected USB port. The control offers exceptional flexibility and reliability, and it includes features unavailable in other manufacturers’ devices—or only available at substantial extra cost:

- Five families of curves: Standard “E,” “K,” and “T” speed curves are supported plus special customizable “coordinating-speed” tap and main curves.

- Superior coordination with upstream protective devices and downstream power fuses: Coordinating-speed curves provide optimal coordination on underground distribution systems.

- Custom curve attributes: Coordinating-speed curves can be easily modified to include two separate definite-time delays.

- Separate phase and ground curves are standard: This enables better coordination with source-side breaker trip settings. Negative sequence and sensitive earth fault protection settings are also provided.

- No extra “wake-up” time: If a fault-interrupter way is closed into a fault, the fault interrupter will trip and clear the fault per the selected TCC, with no additional delay.

- Self-powered: Current transformers on fault-interrupter ways provide sensing and power. No batteries or battery maintenance is needed.

- Simple and straightforward programming and access to status information: All programming software is stored in the control. Programming is completed via a browser-based user interface.

- Event log: The log captures information on the last 64 events captured by the control.

- Diagnostic information: Data is available to assess the status of the control.

- Optional external trip provisions for additional functionality: Input from external sources such as transformer sudden-pressure relays can also trip the fault interrupters.